The use of GCG-P/K membranes for juice processing eliminates the need for pretreatment and associated handling equipment-no more centrifuges, screens, rotary drums, diatomaceous earth, or fining agents. It also does away with the maintenance associated with pretreatment processes, saving you time and money. The latest GCG-P/K modules have a robust backing structure that supports the extended processing requirements of today''''s juice processing plants.

GCG-P/K, designed around the needs of juice processors worldwide:

•No prefiltration, diatomaceous earth, or fining agents needed

•Outstanding flavor, quality, and clarity

•Yields of 96-99+%

•Long-term haze stability

•Fully automated

•Compact design

•Ideal for apple, pineapple, pear, cherry, grape, cranberry, and other juices.

GCG-P/K Systems, combined with last stage of GCG-P/K modules, clarify juices at extremely high yield rates. Up to 98% yield can be achieved without adding diafiltration water.

The GCG-P/K line-up offers the flexibility to address a variet of process requirements:

•Multiple structures: GCG-P19/312,GCG-K19/312,GCG-K37/312,GCG-K19/310

•New 4.3-inch diameter modules and 12-foot lengths

GCG-P/K SYSTEMS

Each GCG-P/K system permits easy installation and comes complete with pump, motor, controls, piping, valves and instrumentation to control a simple once-through batch process.

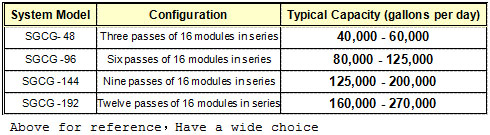

|